What Are Modern Methods of Construction?

The way we build is changing. Quietly, steadily – and in some cases, radically. If you’ve been around the construction industry for more than five minutes, chances are you’ve heard the term Modern Methods of Construction, often shortened to MMC. But what does it actually mean? Is it just another buzzword floating around the industry, or is it something that’s genuinely reshaping how buildings are put together, inspected, and maintained?

For surveyors – whether you’re deep in the commercial world or handling residential properties across the UK and Ireland – understanding MMC isn’t optional anymore. It’s becoming baked into how buildings are designed, procured, built, and ultimately, how you assess their condition. From valuation and defect analysis to compliance and condition reporting, MMC directly impacts how you assess, report, and advise. So yes, it matters. Quite a bit.

In this article, we’ll unpack what modern methods of construction are, why they’re gaining momentum, what kinds of systems and techniques fall under the term, and what it all means for you, the surveyor on the ground (or scaffold).

Contents

- What Are Modern Methods of Construction?

- Why Are MMCs Growing So Quickly?

- Types of Modern Methods of Construction (with Examples)

- Are MMC Buildings Easier or Harder to Survey?

- Are MMC Buildings Easier or Harder to Survey?

- Common MMC Challenges: What Surveyors Should Look Out For

- What This Means for Dilapidations and Long-Term Maintenance

- FAQs About MMC

What Are Modern Methods of Construction?

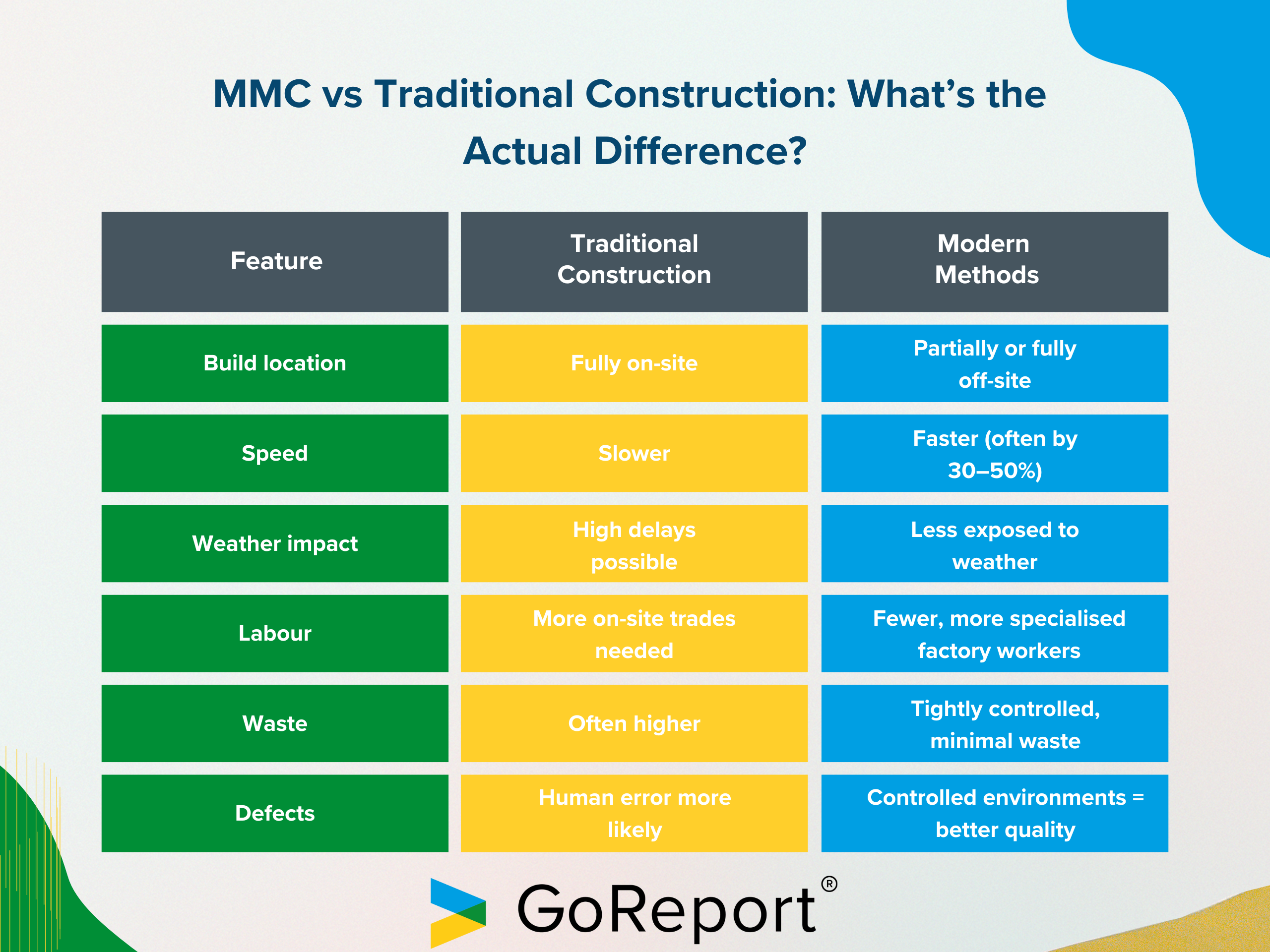

In short, MMC is a broad category that covers off-site manufacturing, advanced material usage, digital construction techniques, and smart assembly systems that aim to improve efficiency, safety, and sustainability across the construction process.

Let’s cut through the jargon. Modern Methods of Construction refers to non-traditional approaches to building, often using off-site manufacturing, newer materials, or streamlined processes to deliver projects faster, safer, and sometimes cheaper. Think prefab, modular, panelised systems, and cross-laminated timber (CLT), basically all those techniques that sound a bit like they belong in a Scandinavian furniture catalogue.

They’re not necessarily “new” – some have been around since the post-war prefab boom – but the way they’re being integrated today is more sophisticated, data-led, and, frankly, more widespread.

Why Are MMCs Growing So Quickly?

So, why have MMCs grown in popularity? Two words: demand and pressure. We need more homes, faster. Commercial buildings are expected to perform better than ever, with tighter regulations, sustainability benchmarks, and client expectations. Traditional methods just aren’t cutting it for volume or speed, and don’t get started on the skilled labour shortage.

MMC is being driven forward by:

- The housing crisis – especially in places like London, Dublin, and major cities across the UK.

- Sustainability targets – low-carbon construction is no longer a ‘nice-to-have’.

- Digital transformation – BIM, IoT, and even AI are reshaping how we think about buildings, not just how we build them.

- Labour and materials shortages – which make controlled, factory-based builds more attractive.

MMC isn’t a trend. It’s an industry adjustment, and if you’re surveying these structures without understanding how they’re built, you’re missing a big piece of the puzzle.

Types of Modern Methods of Construction (with Examples)

Not all MMCs are the same, and different systems require different knowledge when you’re inspecting or reporting. Here’s a quick guide to what’s out there:

- Volumetric (Modular) Construction

Entire sections of a building are constructed off-site (think hotel rooms or student accommodation pods), then transported and stacked on-site. - Panelised Systems

Walls, floors, and roofs made in factories and assembled on-site. Structural Insulated Panels (SIPs) are a common example. - Cross-Laminated Timber (CLT)

Engineered timber sheets layered at right angles, incredibly strong, surprisingly lightweight. - Hybrid Systems

A mix of traditional and modern. You might see steel frames combined with SIPs, or concrete slabs paired with modular interiors. - Thin-Joint Masonry or Lightweight Steel Framing

Faster to build with, lower weight, often more thermally efficient than brick-and-block.

Each of these comes with their quirks, and that matters for surveyors. For example, movement joints in SIP buildings can behave very differently from brick walls, and CLT has its own moisture-related issues if not detailed properly. MMC might change the way buildings go up, but it doesn’t remove the need for close, competent inspection.

How Modern Methods Affect Surveying Practice

The materials might be new, but your job as a surveyor stays the same: assess conditions, report risk, and provide reliable advice. The tools and knowledge, however? Those need to change and grow.

You may find yourself needing to:

- Interpret unfamiliar construction layers (e.g. timber panel composites or factory-fitted membranes)

- Check manufacturer specifications instead of standard building regs

- Use more digital tools on-site to document features quickly and clearly

- Report on long-term maintenance uncertainties, especially for new systems

Good documentation is essential. That’s why more surveyors are turning to structured digital reporting solutions like GoReport, to keep pace with increasingly complex data requirements.

Are MMC Buildings Easier or Harder to Survey?

Here’s the truth: they’re different. Not necessarily harder, but they do come with new expectations. If you’re used to brick-and-block or traditional timber frame, MMC buildings can feel unfamiliar at first.

Some things to keep in mind:

- Details are critical – factory precision is great, but poor on-site assembly can lead to major issues down the line.

- Tracking materials – knowing what type of panel or system is in use isn’t always straightforward, especially post-handover.

- Hidden defects – poor sealing, inadequate ventilation, or incorrect fixings can be hard to spot with the naked eye.

This is where your tech toolkit matters. Using surveying tools and apps like GoReport allows you to capture detailed site notes, tag components by type, and document evidence clearly for clients and contractors alike.

Common MMC Challenges: What Surveyors Should Look Out For

While MMC can improve consistency, it doesn’t mean flawless outcomes. Here are a few recurring issues that surveyors are increasingly flagging:

- Poor integration between systems – where modular meets traditional, junctions can be problematic.

- Lack of as-built documentation – sometimes the final install doesn’t match the drawings, especially when tweaks happen late-stage.

- Moisture ingress – particularly where vapour barriers or detailing are rushed on-site.

- Over-reliance on manufacturer claims – test data might look great, but real-world performance can vary.

These problems don’t always shout. Sometimes they whisper — and that’s why detailed documentation matters. If you haven’t already, brush up on good documentation practice for surveyors.

What This Means for Dilapidations and Long-Term Maintenance

MMC buildings age differently. That’s a fact. So when it comes to dilapidations, expect a few curveballs:

- Some materials aren’t as easy to patch-repair or replace as traditional ones.

- Warranty conditions can be stricter, and breaching them (even unintentionally) can be costly.

- Lifecycle costs may be lower, but only if maintenance is done right. This is where good condition surveys come in.

Understanding how a building was built is just as important as spotting what’s going wrong. No one’s expecting surveyors to become MMC engineers overnight. But understanding how buildings are made, what to look for, and how to report on those elements clearly? That’s extremely important.

Whether you’re surveying SIP homes, assessing CLT offices, or navigating hybrid commercial spaces, GoReport gives you the tools to document, communicate, and stay credible in the field. Ready to see how? Book a free demo today and future-proof your surveying practice.

Frequently Asked Questions

Q: Are modern methods of construction sustainable?

Yes, in theory. Many MMC systems reduce waste, lower carbon during manufacture, and improve thermal performance. But execution matters. Poor design or shoddy install can undo those benefits fast.

Q: Are MMC buildings more prone to defects?

Not necessarily. In fact, factory-built components can be more consistent. But unfamiliarity on-site, lack of coordination, or improper sequencing can introduce risks.

Q: How do I identify which MMC system was used?

Start with project records and manufacturer data. If that’s missing, visual clues (such as modular dimensions, fixings, or finishes) can help, but digital site notes and photos are your best ally.

Q: Will MMC replace traditional construction?

It won’t replace it entirely, but it’s becoming a permanent part of the mix. Surveyors who adapt early will be far better placed in the years ahead.